Sometimes things just don’t go as planned

The past few days I have been fearing that all the work done with the motor/battery pod may have been for nothing as the battery is telling me it is no longer holding a charge after only a few hours of use…Well today I finally verified that the battery is dead indeed. After two full days of charging, running the battery under load from a full charge of ~13v, to 10.5v takes only 2 hours whereas last year when the battery was new, would take around 10-12 hours. It looks like my planned launch at end of February might be delayed a bit as I figure out the best way to crack open the motor pod, replace the battery, and come up with a means to effectively reseal the enclosure.

But there is always a silver lining to the dark clouds…

With the battery tests:

- I was able to test a bearing hack to help alleviate the load the propeller thrust places on the magnetic coupling waterproof barrier.

- I was able to verify that my propeller selection of 5x5e does indeed give enough thrust to move the boat, and only uses 1 to 1.2amps @ ~12.5v!

- The magnetic coupling assembly works great, so far!

Thrust bearing from radial bearing

I’ve since replaced my two Acetal Copolymer washers used as spacers with a ceramic bearing sized appropriately where the propeller adapter sits flush against the smaller inner face of the bearing. The larger outer bearing housing sits against a recessed lip incorporated in the black 3D printed support (which slides over the protruding brass tube from the propeller shaft assembly) which holds the bearing away from the face of the Rulon bearing by about .5mm. This allows enough clearance for the parts to move without interference while absorbing the thrust forces generated by the propeller. Given that radial bearings cannot take too much thrust load, we will see how this works out in the long term. Its a hack, but it’s better than two washers…

LEFT – Cavity to hold the ceramic bearing, MIDDLE – cavity providing clearance for the bearing to spin freely, RIGHT – this cavity fits over the brass tube which houses the prop shaft.

The ceramic bearing support which replaces the two acetal copolymer washers.

Prop adapter installed with bearing hack.

Testing out the battery

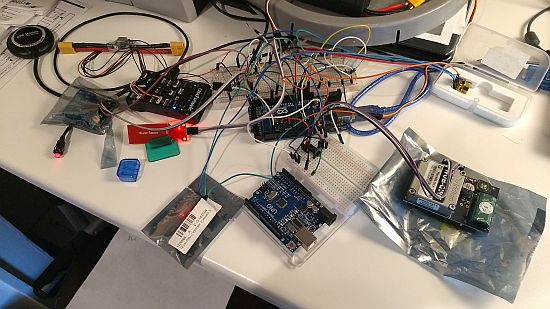

Figured I would set everything up in my garage since it would allow me to easily work on the boat without going outside.

I realized filling this pool would take a while…

So I added two buckets to save a few gallons of water.

10.27v after 2 hours…pretty bad.

Can a car battery still work?

I believe using a car battery (regular starting battery) when brand new can work if not intending the battery to last for an extended period of time or used quickly after the initial deep discharges (a standard starting battery like an automotive battery is rated for 3-13 months if deep cycled). I found that even if the battery is tested for about 1-2 weeks with daily deep discharge rates (~90% DOD), the battery will probably be unable to recover from the damage even if let sitting for a year practically unused and randomly charged back up (My battery was tested the first 2 weeks I received it, then left practically unused for about 13 months).

A better choice would be to use a deep cycle marine or AGM solar battery designed specifically to handle the deep discharge rates a project like this requires. If I had instead used the battery immediately after testing last year, I believe the battery would have lasted for a few months before showing signs of degradation as sulfation and battery plate deterioration wouldn’t have rendered the battery completely dead.

Once I open the battery pod ill likely try and replace the battery under warranty and install the replacement. I still want to see how long my initial choice of power storage will effectively run, and for how long it will continue to do so under near constant 90-100% daily depth of discharge.

so sorry to hear about the battery. first time i read about your project, i was wondering why you weren’t using LiPos.

i wouldnt go with a regular car battery. they are designed for high current, short time. you could only discharge to 60-70% safely, any lower and damage might be unavoidable.

even the deep cycle batteries (solar, wheelchair, etc.) i dont recommend. used 4 of those in the trunk of my car for charging 6s + 12s lipos (at the model-flying field), but after 2 seasons they became useless, and i had not used them THAT much.

I’d really go for LiPo or LiIon.

good luck,

wolfgang

Totally agree with you there about using liPO or lifePO4 batteries for longevity/energy density/and depth of discharge capabilities. I definitely had to cut some corners with costs to try and hit my $1500 budget ?! If I bumped up my budget to $2000-$2500 I think I could have a very robust boat!